Microtrenching is a minimal-destructive and very fast method of laying communication cables in existing traffic areas. In the process, wide joints are cut into the surfaces with diamond blades. Directly after the cut, ductworks are inserted and then the joint is potted. Time and cost-intensive earthworks at the edge of the traffic areas are thus avoided or minimized.

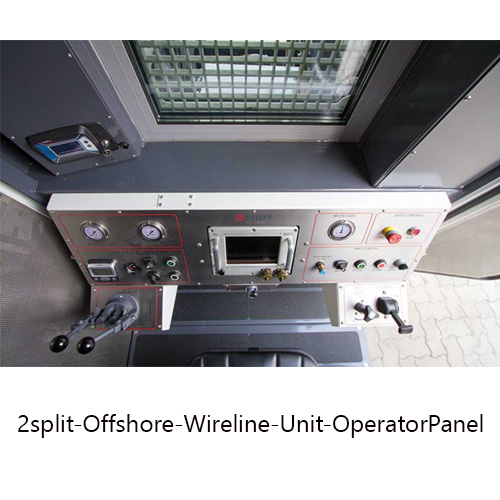

2-split Offshore Wireline Unit

3-split Offshore Wireline Unit

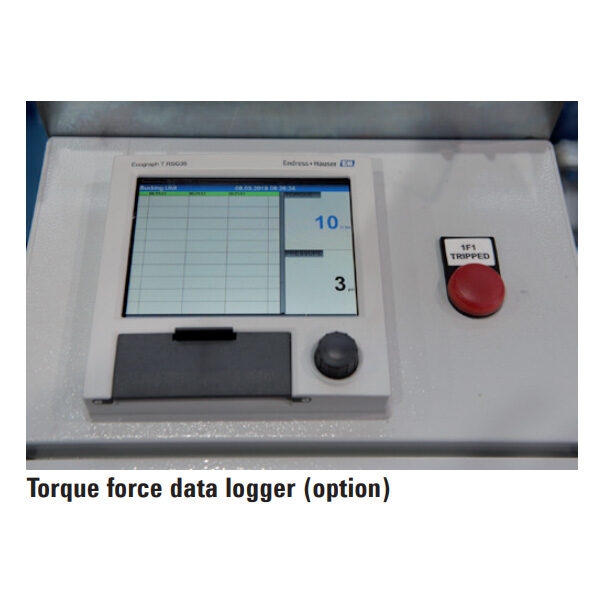

Bucking Unit 18,500 Nm

Bucking Unit 40,000 Nm

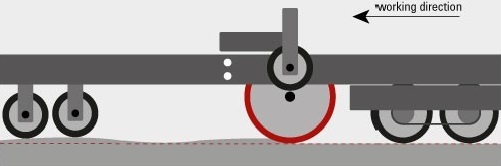

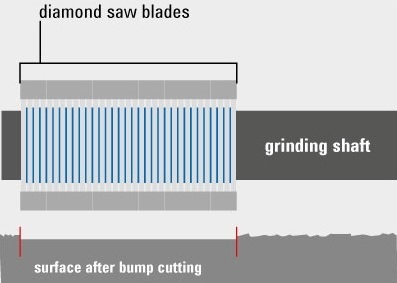

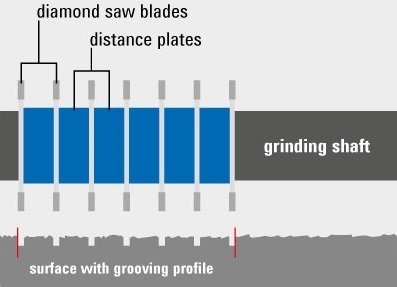

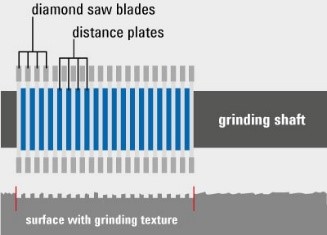

Bump cutter RSG 1750

Bump cutter RSG 4600

Core Saw

Double Support Table

Floor Saw RSF 820

Hydro Vice 220 kN

Joint Brushing Machine RSB 120

The rotating brush (rotates in reverse direction), raises loose material from inside of the joint, such as slurry or small stones, to the front. The result is a largely dust-free joint, which forms the basis for the durability of the sealing compound to be poured into the joint in the next step.

The RSB 120 is equipped with a two-stage air filter which effectively prevents the penetration of dust into the motor. The filter cartridge can be replaced without tools.