- high pull force in combination with a high operation speed

- high performance along the whole depth

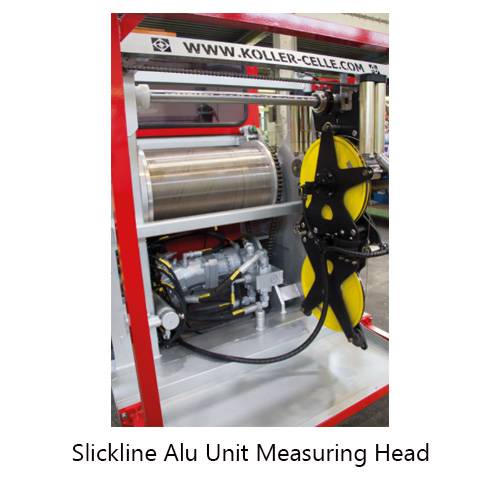

- KOLLER quick drum change system

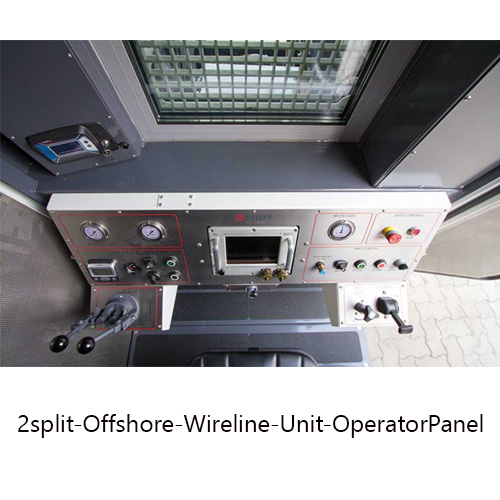

- ergonomically designed operator area

- pneumatic system startup

- powerful hydraulic winch system

- roof flap (winch room) with gas springs

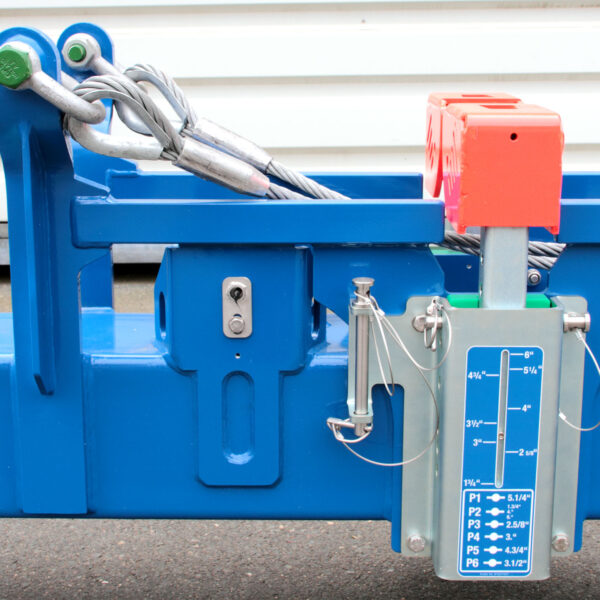

- parallel-working independent electrical, hydraulic and mechanic backup system on the measuring head

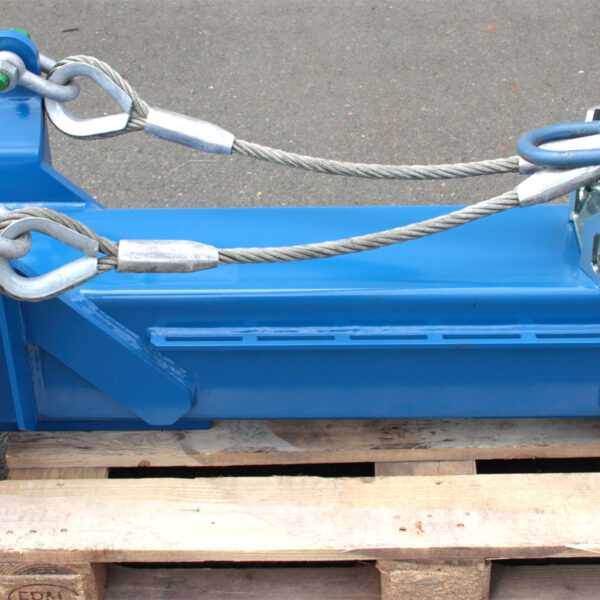

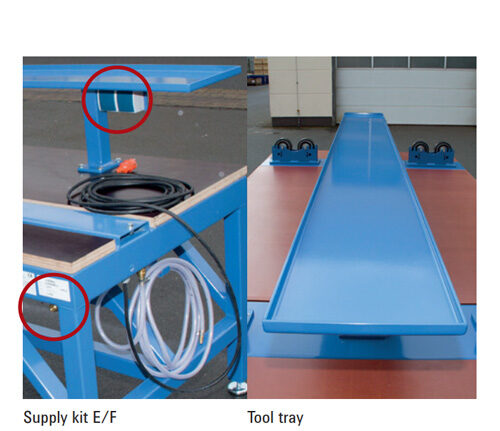

- lifting eyes and forklift pockets enable easy moving

- lifting eyes and forklift pockets enable easy moving

- DNV 2.7-1 Frame, third party approval

Here you can download the 2-split Offshore Wireline Unit catalogue.