Everything

under one roof!

KOLLER Maschinen- und Anlagenbau with its top qualified staff offers you on 4,000-sq.m hall capacity and a factory area of over 40,000-sq.m a complete service, repair / maintenance / revision according to the required standards and regulations of all mobile:

-

Drilling and workover rigs

Drilling and workover rigs -

Water well drilling plants

Water well drilling plants -

Horizontal drilling devices (HDD)

Horizontal drilling devices (HDD)

-

Special machines, e.g., excavators, cranes, road construction machinery etc.

Special machines, e.g., excavators, cranes, road construction machinery etc. -

Workshop equipment

Workshop equipment

Our service offer

Mechanical works

-

Disassembly/assembly of all mechanical components

Disassembly/assembly of all mechanical components -

Setting and adjustment work

Setting and adjustment work -

Testing and repair for e.g., bearings, cylinders etc.

Testing and repair for e.g., bearings, cylinders etc. -

Repairs of all mechanical parts

Repairs of all mechanical parts -

Turning, milling and drilling

Turning, milling and drilling -

Sawing, bending

Sawing, bending

Electrical works

-

Electrical check-up

Electrical check-up -

Renewal of damaged components and lines

Renewal of damaged components and lines -

Error detection in electrical control systems

Error detection in electrical control systems -

Upgrade of electrical equipment and components

Upgrade of electrical equipment and components -

PLC programming

PLC programming -

Engineering and documentation

Engineering and documentation

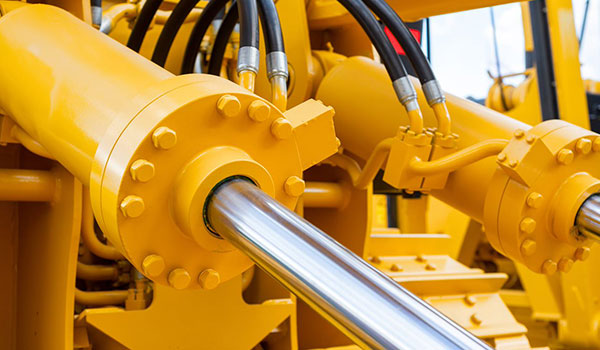

Hydraulic works

-

Hydraulic cylinder maintenance

Hydraulic cylinder maintenance -

Check and adjustments of hydraulic systems

Check and adjustments of hydraulic systems -

Inspection and replacement of damaged hydraulic hoses

Inspection and replacement of damaged hydraulic hoses -

Creation and editing of hydraulic plans

Creation and editing of hydraulic plans -

Inspection and replacement of hydraulic valves and fittings

Inspection and replacement of hydraulic valves and fittings

Pneumatic works

-

Check and adjustments of pneumatic systems

Check and adjustments of pneumatic systems -

Inspection and replacement of damaged pneumatic hoses

Inspection and replacement of damaged pneumatic hoses -

Creation and editing of pneumatic plans

Creation and editing of pneumatic plans -

Inspection and replacement of pneumatic valves and fittings

Inspection and replacement of pneumatic valves and fittings

Steel construction and welding

(DIN EN 1090/1, 1090/2 EN 3834)

-

Repair welding

Repair welding -

Repair or replacement of steel frames

Repair or replacement of steel frames -

Treatment of steel, stainless steel, aluminum

Treatment of steel, stainless steel, aluminum -

Welding procedures MAG (135, 136), MIG (131), WIG (141), E-hand (111)

Welding procedures MAG (135, 136), MIG (131), WIG (141), E-hand (111) -

Straightening work (flame and cold straightening)

Straightening work (flame and cold straightening) -

Handling of large components up to 20 tons

Handling of large components up to 20 tons

Surface

treatment works

-

Pre-treatment (sandblasting, pickling etc.)

Pre-treatment (sandblasting, pickling etc.) -

Powder coating

Powder coating -

Wet varnishing

Wet varnishing -

Galvanising / hot-dip galvanizing

Galvanising / hot-dip galvanizing -

Phosphating

Phosphating -

Anodising

Anodising -

Etc.

Etc.

In addition to hands on work,

we provide you on request with the following documentation:

Workover rigs have to be completely overhauled every 10 years. Firstly, the rig is completely dismantled. Related to a strict revision plan, diverse works at the mechanical, hydraulic and electric assemblies is carried out. After a fresh paint job, assembly and technical acceptance the workover rig is ready for the next ten years in the oil field.

Does your machinery require an upgrade

or a functional test?

We are looking forward to your call!