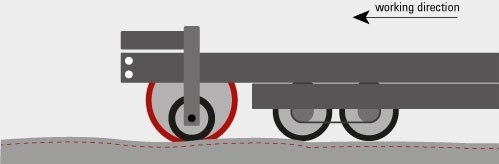

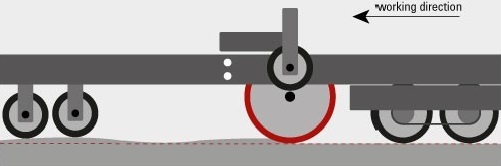

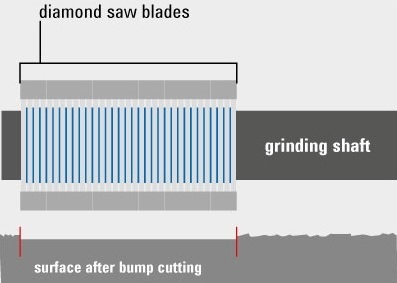

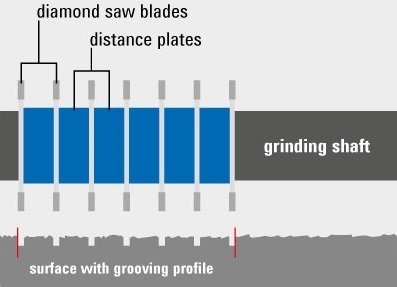

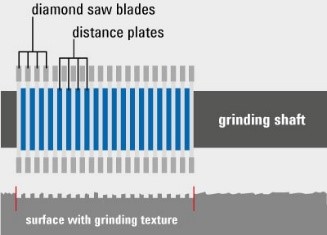

Microtrenching is a minimal-destructive and very fast method of laying communication cables in existing traffic areas. In the process, wide joints are cut into the surfaces with diamond blades. Directly after the cut, ductworks are inserted and then the joint is potted. Time and cost-intensive earthworks at the edge of the traffic areas are thus avoided or minimized.

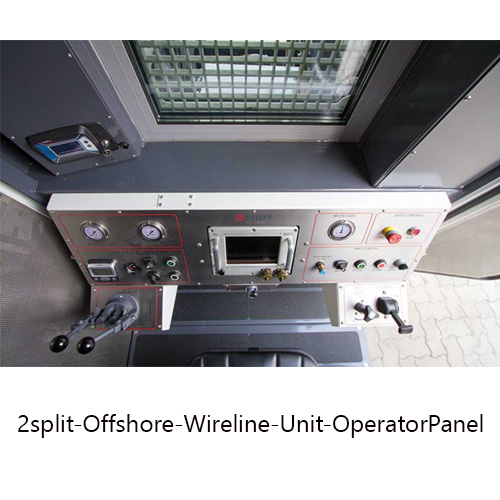

2-split Offshore Wireline Unit

3-split Offshore Wireline Unit

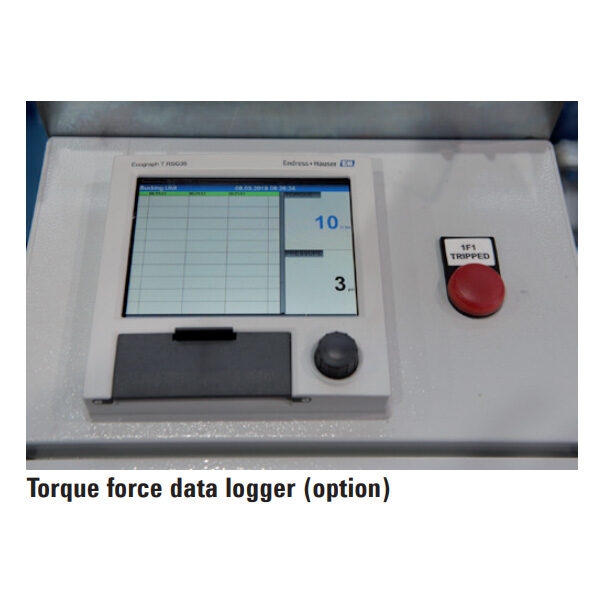

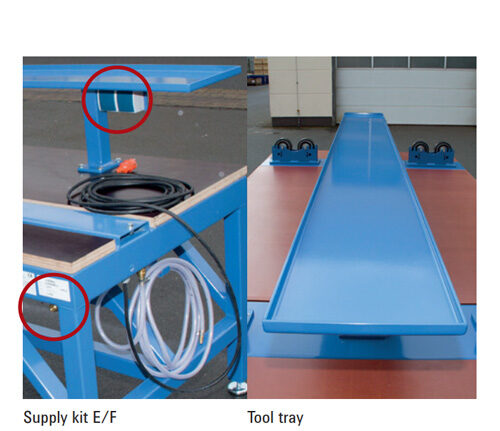

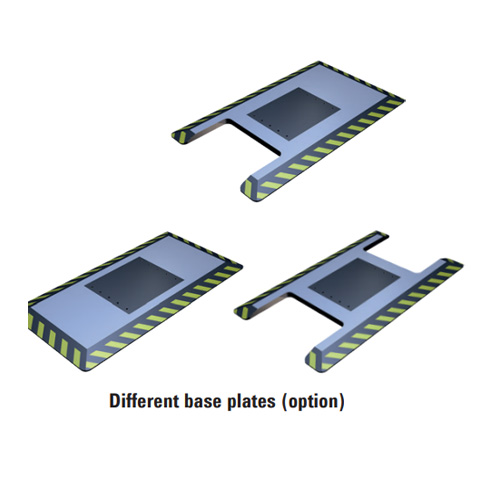

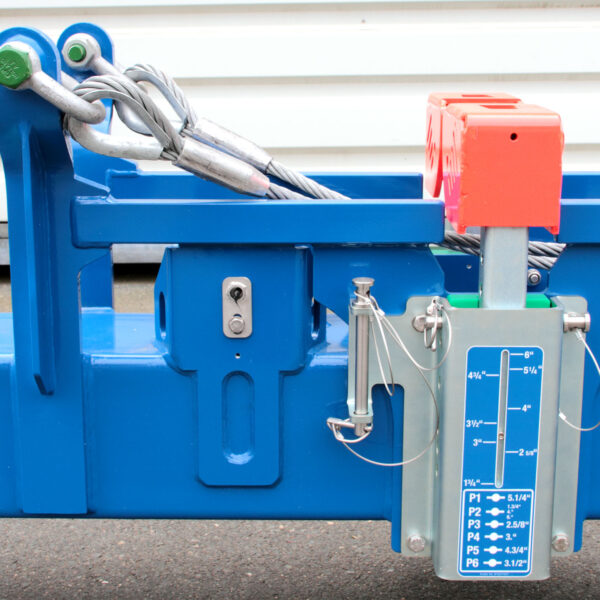

Bucking Unit 18,500 Nm

Bucking Unit 40,000 Nm

Core Saw

Double Support Table

Hydro Vice 220 kN

Laydown frame

Lightweight Wireline Unit

Mobile heavy duty Double Workover Rig 90 tons

- SISU heavy duty truck with Caterpillar engine, 10x10 drive for extreme off-road capabilities

- road approval (Germany, Romania) dimensions and weight within the permitted legal limits for special trucks

- 6 hydraulical supports, mechanically locked

- 90 tons hook load

- drawworks with closed-loop cooling and API 7K monogram

- sand-line drum for 3000 m working depth (higher depths possible)

- powerful hydraulic by truck engine via Allison transmission 4700 OFS

- mast with automatic lock in end position (retracted and extended) and API 4F monogram

- electric safety according to EN 60204

- automatically uplifting working platform while mast telescoping

- stairs foldable for transport

- store capacity for 140 double tubings up to 31/2“

- turning circle under < 20 m

- working temperature range -29°C / +45°C (+55°C for special operations)