Floor Saw overview

- drive motor with exhaust gas cleaning technology, installed in an extremely torsion-resistant U-frame to reduce vibration

- hydraulic feed drive and hydraulic steering improve maneuverability and comfort

- powerful main and auxiliary hydraulics for driving the system attachments

- central hydraulic cylinder and stable double column guide for mounting kits standard cut, longitudinal cut and grooving

- flexible mounting options for operator station, depending on use and/or operator requirements

- intuitive operation via joystick and keypad, display for control and monitoring functions

- all-wheel drive available on request (factory conversion only)

Durable, sustainable and smart design

Often, design features that are not visible at first glance are of elementary importance for the sustainable benefit of a working machine.

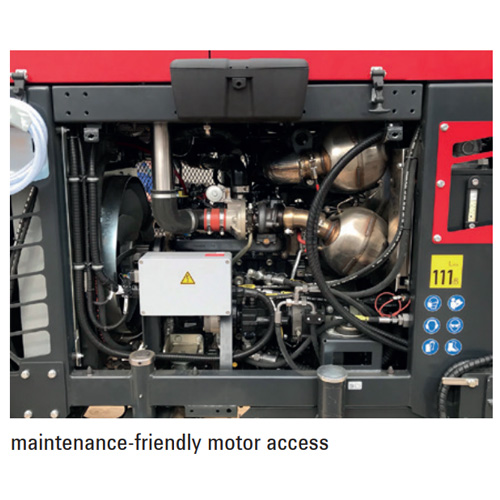

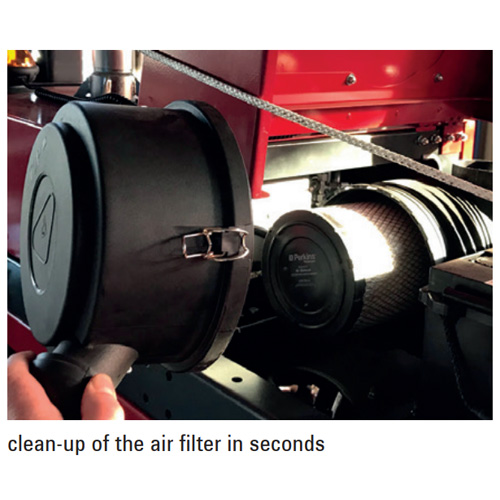

The rugged frame with mounting options on all sides or the use of high-quality and durable components as well as aggregates from reputable manufacturers are examples of this. Since particular attention was paid to the dimensions, the RSF 820 has a very compact design. Of course, the machine is also equipped with the latest exhaust gas treatment. Non-productive times for maintenance work are reduced to a minimum by an optimal access to the engine and other maintenance-relevant parts. A clean-up of the air filter consumes a few seconds only, for example.

Reliability of supply first and foremost

For sure, a defect can also occur on an RSF 820. To keep downtime as short as possible, we are building up a close-knit service network. This is how we ensure the fast and reliable supply of spare parts and services.

Customized solutions?

Even the most sophisticated machine cannot cover every conceivable application. Our experienced engineers will be happy to advise you, even on site. We adapt your machine exactly to your special requirements. Whatever challenges you have, we will find a solution together.