- compact skid design

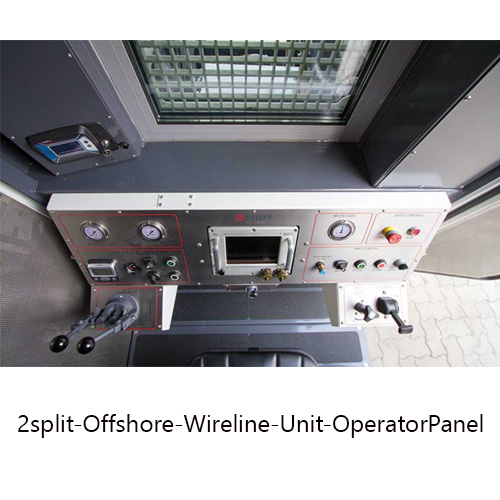

- intergrated electric driven hydraulic system

- simple operation with over tension protection

- adaptable to wide range of transport drums

- suitable for slickline up to 0.180“

- suitable for braided line up to 5/16“

- maximum transport drum diameter 1,250 mm

- CE-marked

- movable drip pan unter the transport drum

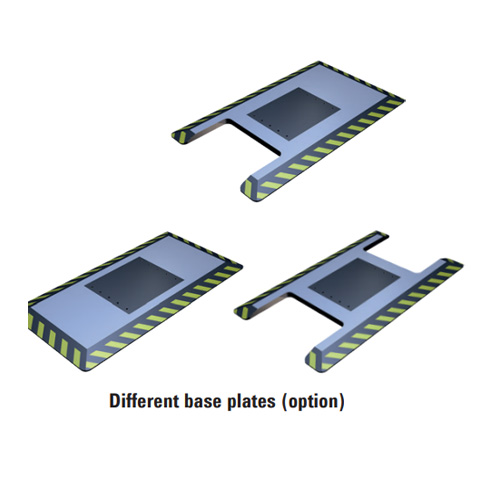

- mounting plates on each corner for proper fixture to the ground

- weather tarpaulin cover in RAL 3002 for the entire unit (or other available RAL shade)

Here you can download the Wireline Spooling Unit catalogue.