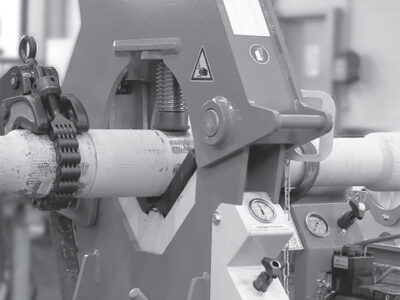

- Partly with strap for fastening tool or workpiece

- To prevent unintentional rotating, the support rollers are arrestable.

- Grounded for application within ESD (electrostatic discharge) environments

- Non-magnetic stands prevent magnetic fields when working on sensitive measuring tools.

Flexible head versions

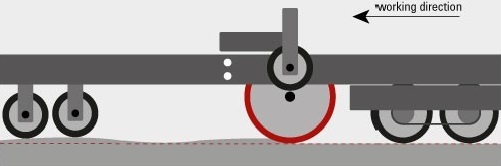

The support roller console can be tilted for up to 5 degrees in both directions. Thus, the entire surface of the support rollers is also used in oblique tool rest.

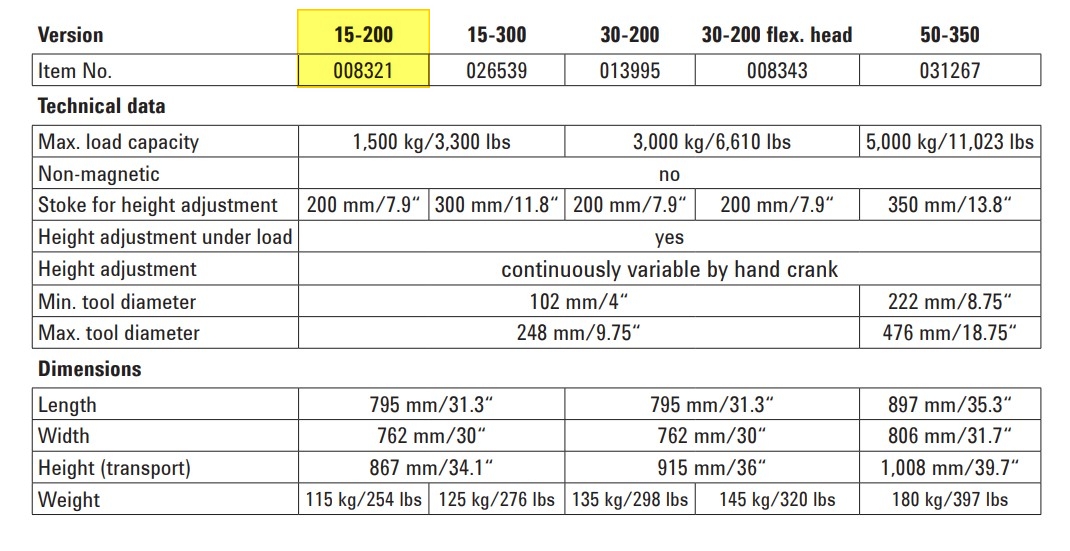

Stand 15-300

Special edition of stand 15-200, see specifications and product catalogue for more details.