Microtrenching ist ein zerstörungsarmes und sehr schnelles Verfahren zur Verlegung von Kommunikationskabeln in bestehenden Verkehrsflächen. Dabei werden mit Diamantscheiben breite Fugen in die Oberflächen geschnitten. Unmittelbar nach dem Schnitt werden Leerrohre eingelegt und anschließend die Fuge vergossen. Zeit- und kostenintensive Erdarbeiten am Rande der Verkehrsflächen werden so vermieden bzw. minimiert.

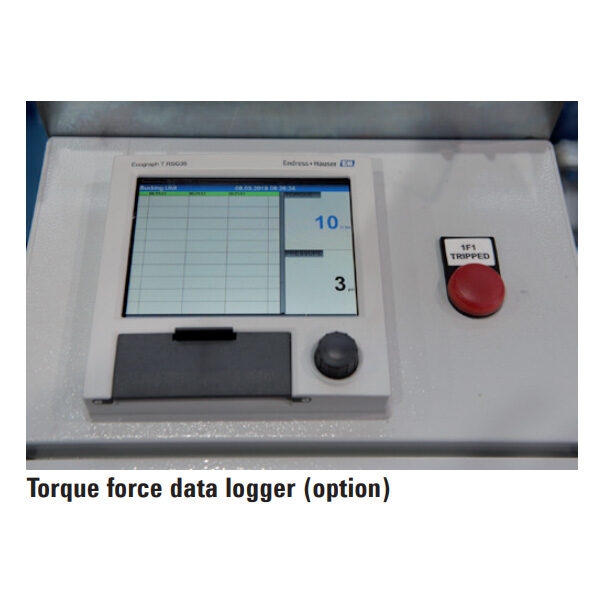

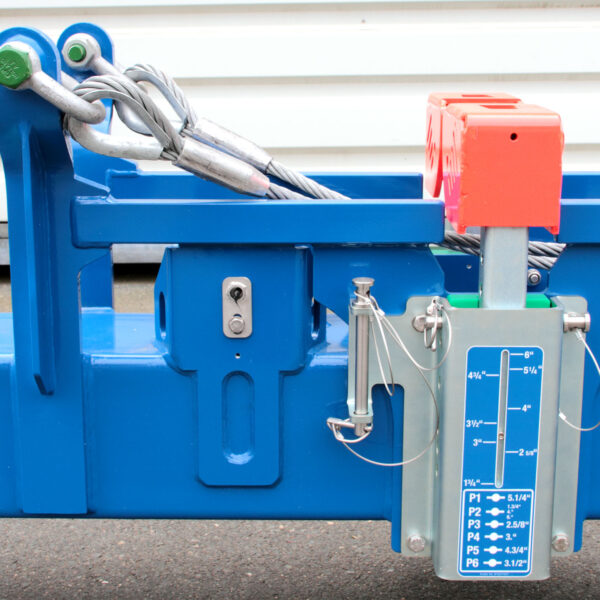

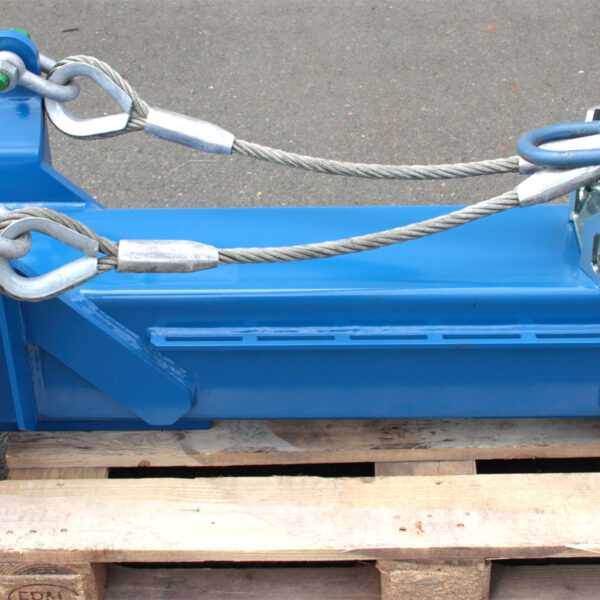

Bucking Unit 18,500 Nm

The bucking unit have been designed to make and break screwed connections with high torques. The unit is a combination of a KOLLER hydraulic vice 220 kN and a hydraulic operated chain tong. For the basic unit without electronic data logger, no electrical supply is required. Both, the hydraulic vice and the tong are supplied by pressure air driven hydraulic power packs. Since the bucking unit is mounted on a solid steel frame with forklift truck pockets, it is transport friendly and can be moved easily on site.

Bucking Unit 40,000 Nm

The bucking unit has been designed to make and break screwed connections with high torques. The unit is a combination of a KOLLER hydraulic vice 220 kN and a hydraulic operated chain tong. For the basic unit without electronic data logger, no electrical supply is required. Both, the hydraulic vice and the tong are supplied by pressure air driven hydraulic power packs. Since the bucking unit is mounted on a solid steel frame with forklift truck pockets, it is transport friendly and can be moved easily on site.

Core Saw

The Koller Core Saw is used to cut the inner tube with drill core into 900 – 1000 mm sections. The conical drums of the connected lay down frame feeds the inner tube to the saw, where an air-powered diamond or corundum saw blade cuts it into the sections described above. The inner tubes can be made of aluminum alloy, fibreglass or heat-treatable steel. In most cases, aluminum tubes are used, so the equipment is optimised to effectively cut filled-core aluminium tubes. The core saw is suitable for offshore and onshore applications

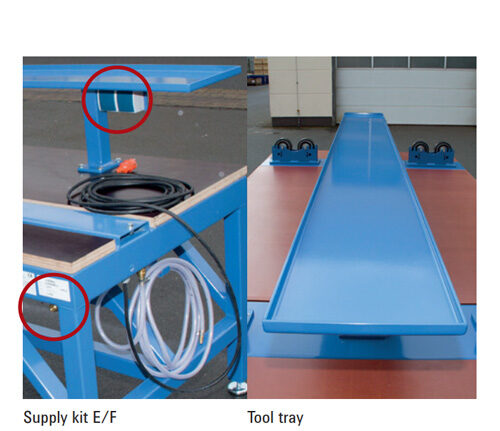

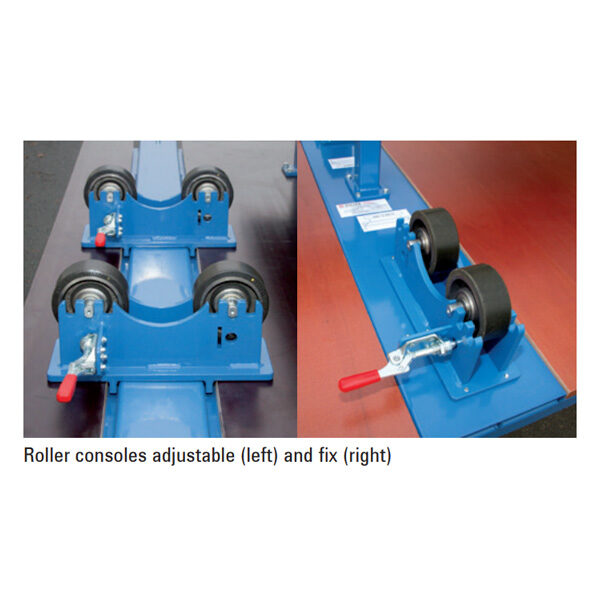

Double Support Table

KOLLER support tables are made for lay down and work on downhole tools or other cylindrical parts in an ergonomically working position. Since the workpiece is placed on rollers, it can be easily turned to the right position. For lock it in position, the rollers are arrestable. In the single version, the distance between the roller consoles is adjustable. The tables are equipped with a stable elevated tray for tooling equipment, parts or measuring devices. A circumferential edge prevents roll down of parts or drip down of liquids to the workplace.

Hydro Vice 220 kN

The hydraulic vice have been designed for short-term clamping of downhole tools or other cylindrical workpieces. The 3-point clamping is carried out via a manual spindle and a hydraulically operated prism. The spindle is turned down to the diameter of the workpiece. Then the required clamping force is generated by the hydraulic lifting of the prism. The prism is equipped with specially textured jaws that effectively prevent the workpiece from rotating.

Laydown frame

A perfect tool to ensure safe core samples extraction from the core string on surface. The frame allows to lay down the core samples horizontally without damage, for example directly from the rig floor onto the catwalk. The frame can also be coupled directly to the Core Saw for the core samples to be cut into transportable pieces with protective tube using the saw.

Single Support Table

KOLLER support tables are made for lay down and work on downhole tools or other cylindrical parts in an ergonomically working position. Since the workpiece is placed on rollers, it can be easily turned to the right position. For lock it in position, the rollers are arrestable. In the single version, the distance between the roller consoles is adjustable. The tables are equipped with a stable elevated tray for tooling equipment, parts or measuring devices. A circumferential edge prevents roll down of parts or drip down of liquids to the workplace.

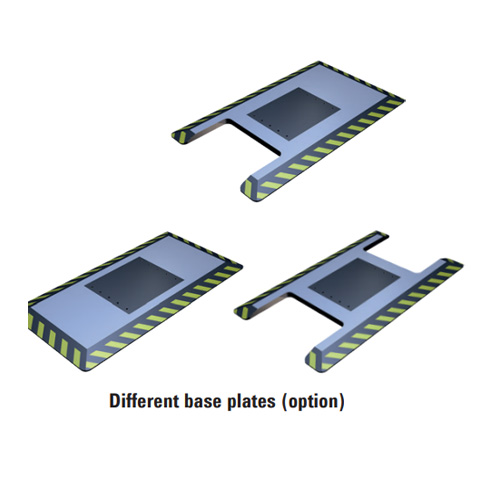

Stand 10-350 non-mag

Stands are used for cranless assembly, disassembly and storing of downhole tools or other cylindric parts. For different tool diameters, the distance between the support rollers is adjustable. To allow working in an ergonomic position, the height of the stands can be adjusted. Except type 15-350 non-mag, all stands are fitted with transport rollers for move them without load.

Stand 15-200 / 15-300 see specifications

Stands are used for cranless assembly, disassembly and storing of downhole tools or other cylindric parts. For different tool diameters, the distance between the support rollers is adjustable. To allow working in an ergonomic position, the height of the stands can be adjusted. Except type 15-350 non-mag, all stands are fitted with transport rollers for move them without load.

Stand 15-350 non-mag

Stands are used for cranless assembly, disassembly and storing of downhole tools or other cylindric parts. For different tool diameters, the distance between the support rollers is adjustable. To allow working in an ergonomic position, the height of the stands can be adjusted. Except type 15-350 non-mag, all stands are fitted with transport rollers for move them without load.