- Air drive hydraulic power pack with foot pedal operation by Enerpac

- Hydraulic pressure regulator for adjust the clamp force

- Pneumatic pressure regulator for adjust the air supply

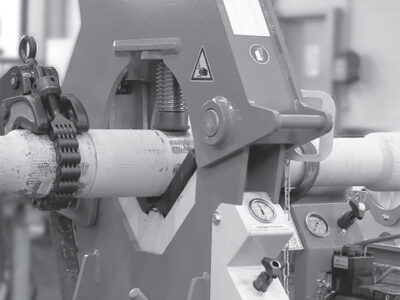

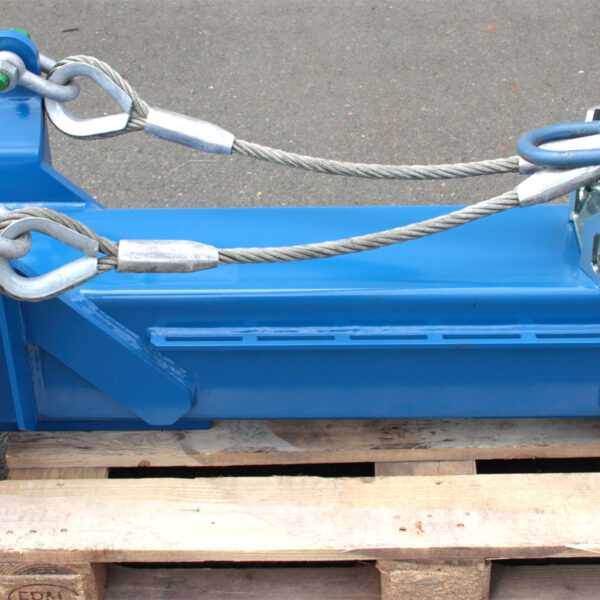

Hydro Vice 220 kN

The hydraulic vice have been designed for short-term clamping of downhole tools or other cylindrical workpieces.

The 3-point clamping is carried out via a manual spindle and a hydraulically operated prism.

The spindle is turned down to the diameter of the workpiece. Then the required clamping force is generated by the hydraulic lifting of the prism.

The prism is equipped with specially textured jaws that effectively prevent the workpiece from rotating.

Kategorien: Clamping, Öl & Gas Werkstattausrüstung Branchen: Mechanical Engineering, Öl und Gas, Well Servicing

Beschreibung

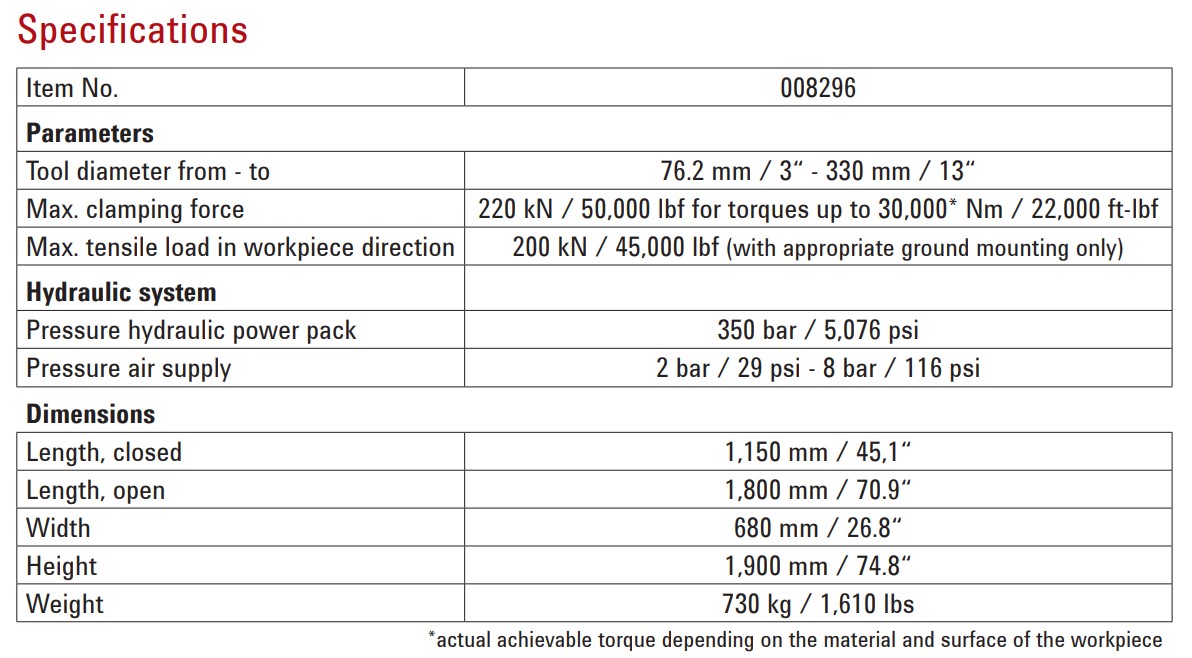

Specifications

Specifications

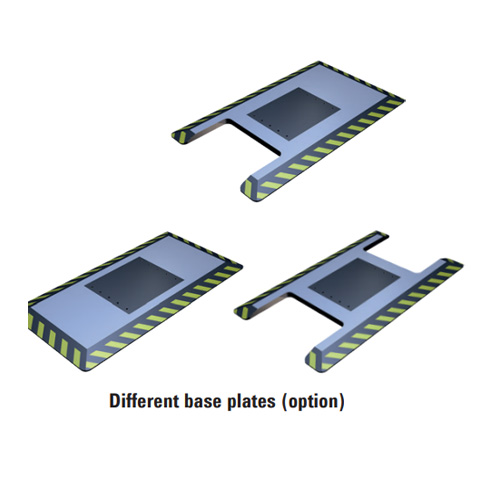

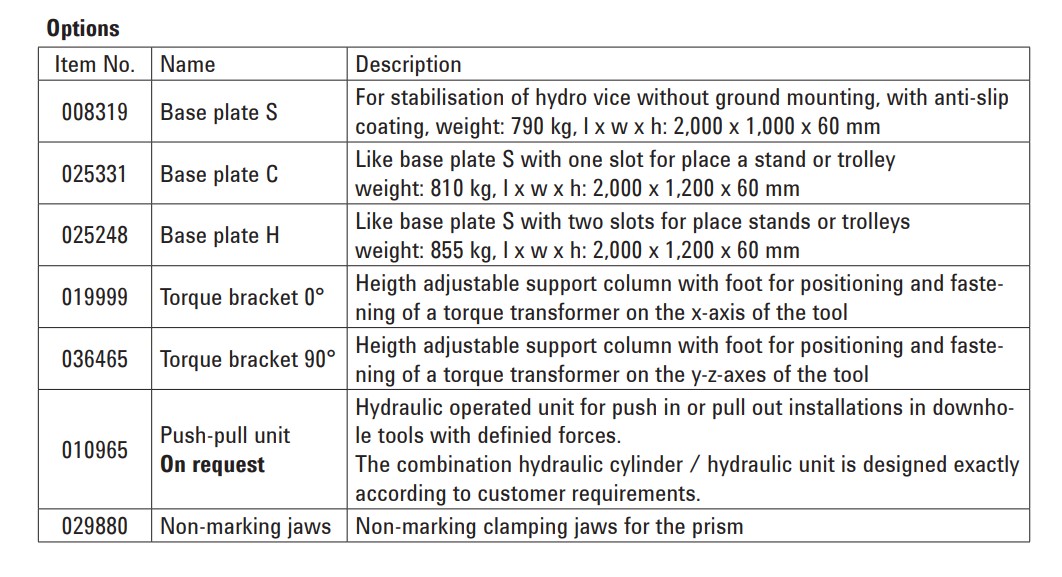

Options

Options

Ähnliche Produkte

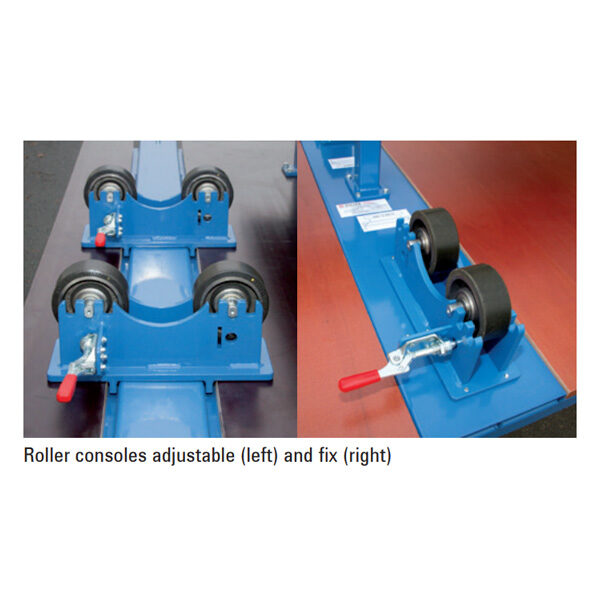

Single Support Table

KOLLER support tables are made for lay down and work on downhole tools or other cylindrical parts in an ergonomically working position. Since the workpiece is placed on rollers, it can be easily turned to the right position. For lock it in position, the rollers are arrestable. In the single version, the distance between the roller consoles is adjustable. The tables are equipped with a stable elevated tray for tooling equipment, parts or measuring devices. A circumferential edge prevents roll down of parts or drip down of liquids to the workplace.

Laydown frame

A perfect tool to ensure safe core samples extraction from the core string on surface. The frame allows to lay down the core samples horizontally without damage, for example directly from the rig floor onto the catwalk. The frame can also be coupled directly to the Core Saw for the core samples to be cut into transportable pieces with protective tube using the saw.

Stand 10-350 non-mag

Stands are used for cranless assembly, disassembly and storing of downhole tools or other cylindric parts. For different tool diameters, the distance between the support rollers is adjustable. To allow working in an ergonomic position, the height of the stands can be adjusted. Except type 15-350 non-mag, all stands are fitted with transport rollers for move them without load.

Washing Plant L-700

The KOLLER Washing Plant L700 is used for degreasing and cleaning of parts or tools. Two programs are available, automatic and manual. For manual cleaning by hand brush the washing table will be lifted to an ergonomic working height. The KOLLER Washing Plant L700 is especially designed environmentally friendly. During the cleaning process the fluid is continuously circulated, filtered and at the end oxygenated with a separate oxygen pump. Therefore its liftime is very long.

Trolley 50-200 long / 50-200 see specifications

Trolleys are used for cranless assembly, disassembly and transport of downhole tools or other cylindric parts. For different tool diameters, the distance between the support rollers is adjustable and for different tool lengths, the center bar is stepless extendable. To allow working in an ergonomic position, the height of the trolley can be adjusted. Each trolley is grounded and can be used in ESD (electrostatic discharge) environments out of the box. A turnable tray for tooling equipment is optional available.

Trolley 30-200

Trolleys are used for cranless assembly, disassembly and transport of downhole tools or other cylindric parts. For different tool diameters, the distance between the support rollers is adjustable and for different tool lengths, the center bar is stepless extendable. To allow working in an ergonomic position, the height of the trolley can be adjusted. Each trolley is grounded and can be used in ESD (electrostatic discharge) environments out of the box. A turnable tray for tooling equipment is optional available.

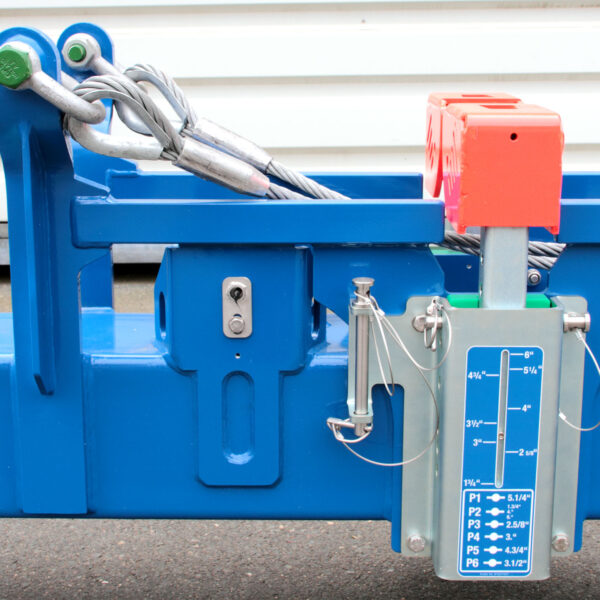

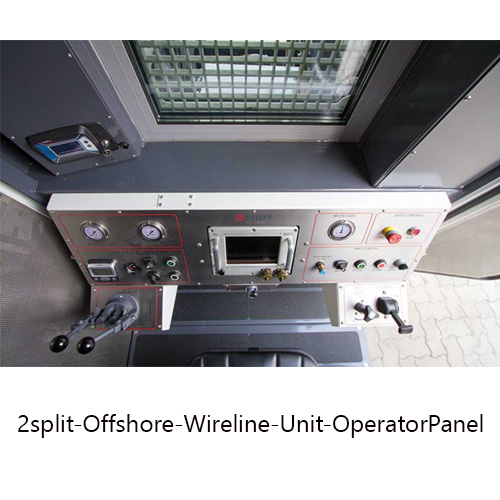

2-split Offshore Wireline Unit

The KOLLER 2-Split Offshore Wireline Unit has been designed for measurements, slickline and e-line activities with wire capacities above 7,650 m / 25,000 ft. It is suitable for both offshore and onshore applications. The 131 HP guarantees maximum pull force and speed at any depth, even with heavy tools. One of the new features of the power pack is a maintenance free flame trap together with a fault analytic system. The optional available battery startup makes the system independent of any external power supply.

3-split Offshore Wireline Unit

The KOLLER 3-split Offshore Wireline Unit has been designed for measurements and workover activities with wire capacities above 7,650 m / 25,000 ft. The 3-skid layout is separated in a winch, an operators and a hydraulic power pack container. The hydraulic pump / motor combination guarantees high pull force and speed at any depth.