- Air drive hydraulic power pack with foot pedal operation by Enerpac

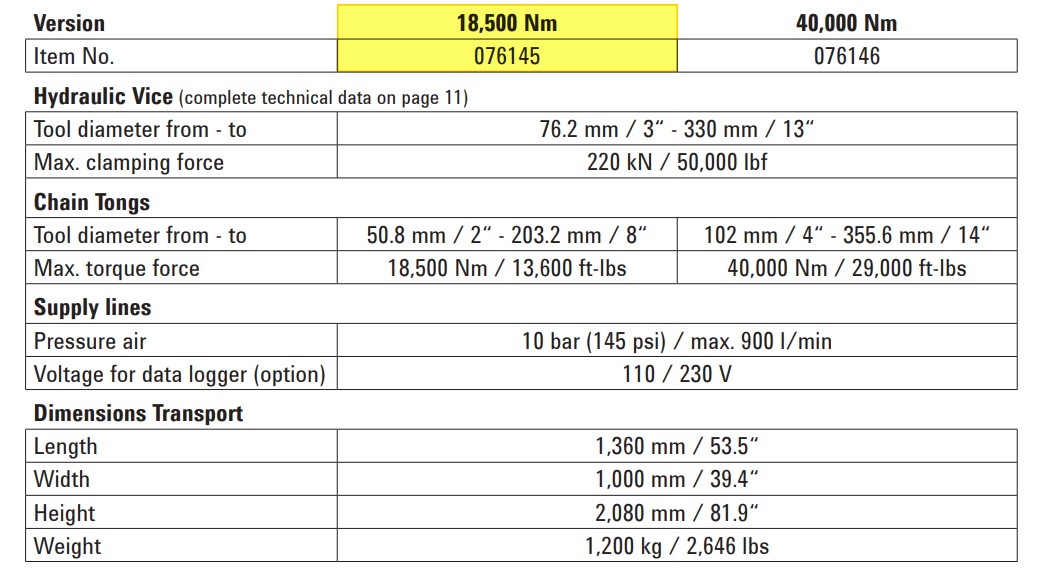

- Two versions available, 18,500 Nm and 40,000 Nm

- Loading by crane from top (no sideward loading)

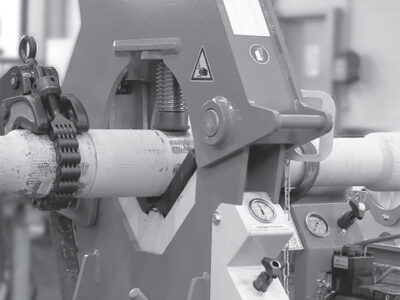

- Tongs laterally adjustable via slider

- Height-adjustable stand for horizontal alignment of the tool

- Rotatable auxiliary crane for moving the chain tong from screwing to loosening

- CE declaration according to EC machinery directive 2006/42/EC

Here you can download the Bucking Unit and Workshop Equipment catalogue.