Trolley profile

- Very good maneuverable by steerable wheels

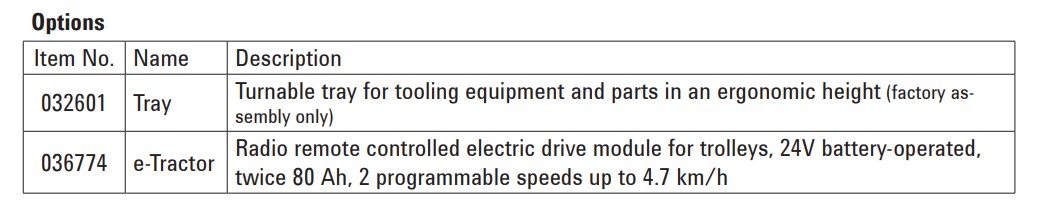

- Secure strap for fastening tool or workpiece

- To prevent unintentional rotating, the support rollers are arrestable.

- Guide wheels with park brakes and steering arresters

- Also movable under load

- Bumper guards on both sides

- Hand crank for height adjustment removable

- Battery-operated electric tractor with radio remote control optional available